More safety in the field of sterile water treatment

More safety in the field of sterile water treatment thanks to continuous online monitoring of silicates

The Central Sterile Supply Department (CSSD) of the General Hospital Celle (AHK Celle) is one of the largest local sterile supply centers in the region and has, among other things:

- 9 washer-disinfectors

- 2 mobile washer (CWA)

- 1 formaldehyde sterilizer

- 3 steam sterilizers (1x 9 STE & 2×18 STE)

In addition to reprocessing contaminated medical devices for the AHK Celle, the ZSVA Celle also reprocesses devices for hospitals in the Hannover and Hamburg regions, as well as for medical practices that do not have their own reprocessing facilities.

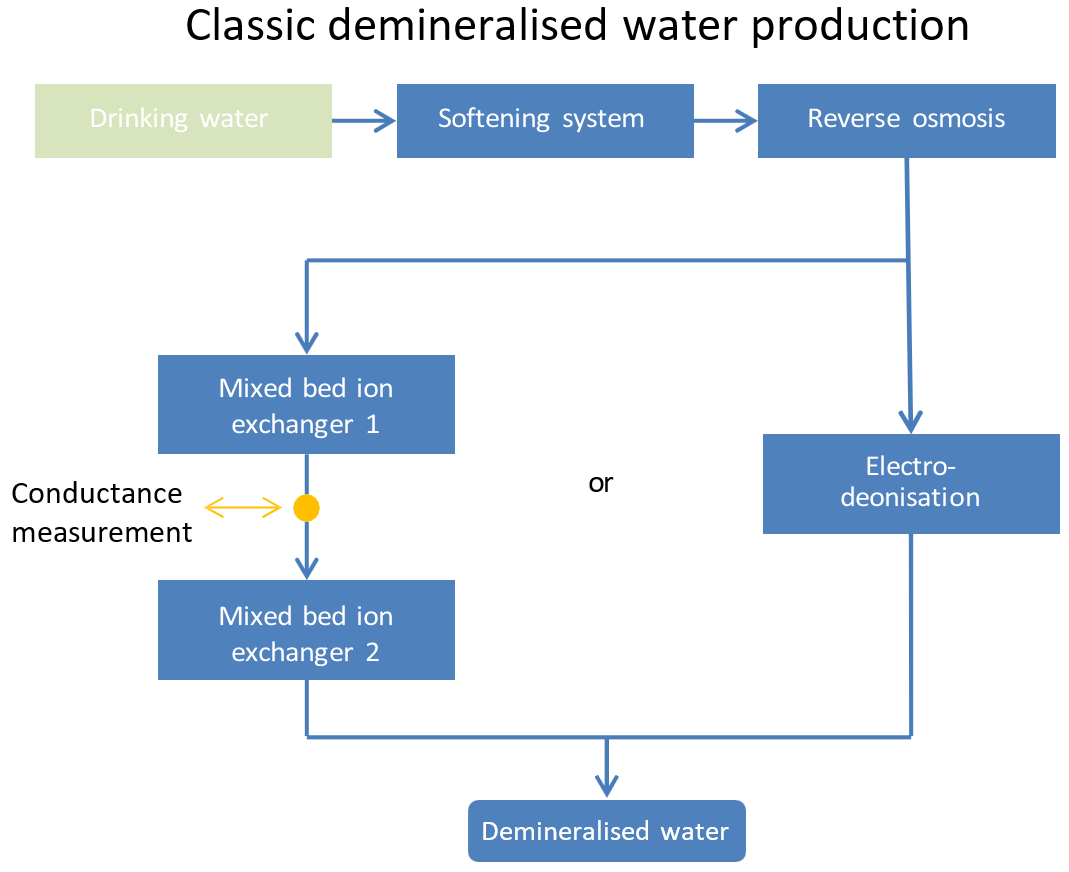

The classic generation of demineralised water for the generation of pure steam for autoclaves includes a softening system with downstream reverse osmosis. The last stage of the production process is either two series-connected mixed-bed ion exchangers or an electrodeionization. The monitoring of the exchanger capacity is done by measuring the conductivity after the first mixed-bed filter. If the conductivity increases, the capacity of the filter material is exhausted and a change or a regeneration must take place. In this context, it should be noted that the breakthrough of silicate (silicate slippage) precedes the increase in conductivity and thus takes place in advance.

Particularly in the field of sterile processing, the issue of silicate deposits should not be underestimated due to the resulting problems. Silicates have a crystalline structure and cannot be easily removed from the affected media using conventional methods.

Possible causes for the contamination include the carry-over of silicates from cleaning, insufficient rinsing and neutralization, silicic acid leakage in the demineralised water preparation, as well as silicates in the feed water of the autoclave.

In the summer of 2017, the company TS-Wassertechnik Tempel & Scholz GmbH modernized the demineralised water treatment system at the ZSVA Celle. As part of the work, all four demineralised water lines were equipped with online monitoring for SiO2. To meet the measurement requirements, the Testomat 808 SiO2 was chosen, a product from the Hildesheim-based company Gebrüder Heyl Analysentechnik mbH. For more than 60 years, the company has specialized in the field of online measurement technology for water-soluble substances. The Testomat 808 SiO2 was specially developed for this measurement task and monitors the concentration of SiO2 in the process chain fully automatically.

During implementation, great importance was attached to a high level of process reliability and functionality. For each demineralized water line, a device was installed downstream of the mixed-bed ion exchanger 1. The devices continuously analyze the concentration of SiO2 at short time intervals, whereby the programmed and thus to be adhered limit value of 0.3 mg/l is set very low. In the event that the limit value is exceeded, the building services staff receive a corresponding message and can initiate the necessary replacement of the affected cartridges.

Both the employees of TS-Wassertechnik Tempel & Scholz GmbH and the technical staff on site are highly satisfied with the solution found after more than 8 months of operation. In addition to the reduced time required for manual analysis by the operating personnel, it was also found that the demand-based regeneration of the filters has led to a reduction in the associated effort and the resulting costs.

The newly installed technology will also be presented to the external auditors as part of the upcoming certification audit in order to emphasize the innovative ability and future orientation of the AHK Celle in the area of the procedural safety of water treatment.

Demineralised water treatment of the AKH Celle

(Plant engineering: TS-Wassertechnik Tempel & Scholz GmbH; 38518 Gifhorn)